Handling of DRYSURF

Handling of DRYSURF

1. Removing oil and foreign substances from the surface (parts)

・Remove oil and foreign substance from the surface (parts) in advance

・Any oil or foreign substance remaining may result in coating layer not forming properly. It could also cause foreign substance contamination.

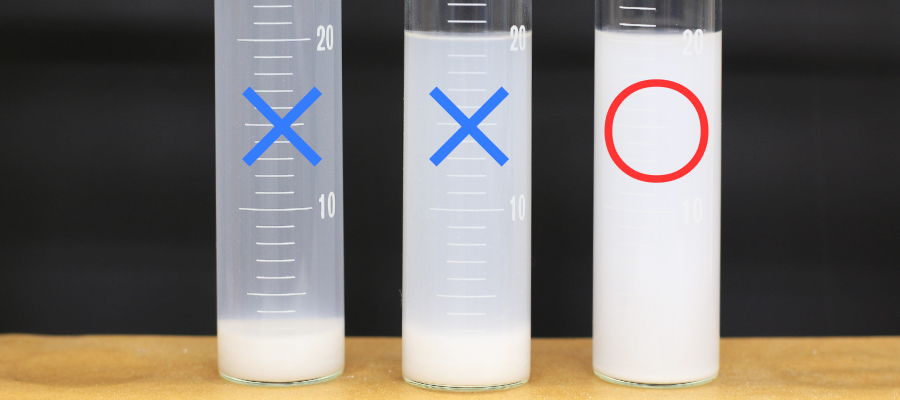

2. Agitating DRYSURF

・Shake the can and mix the content well before use so that the active ingredient is evenly dispersed in the solution. 。

※Note: Do not use while the active ingredient is isolated in the solution.

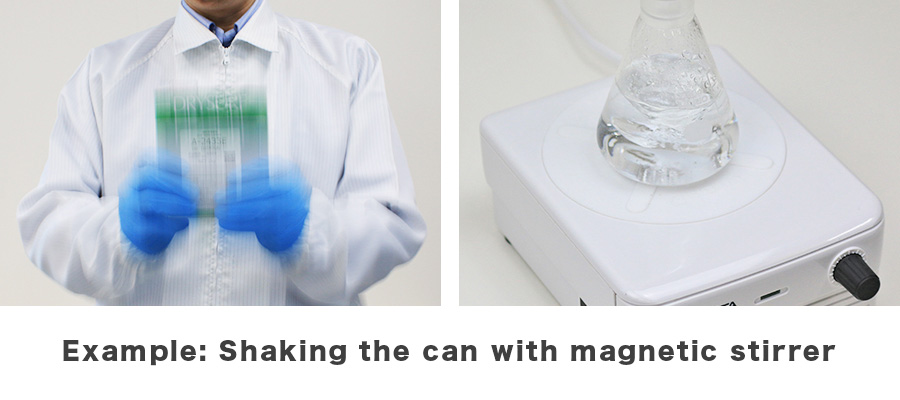

How to agitate it

1. Shake the can up and down to hit the liquid to the lid for about 10 seconds (or 20 times). It will mix well if you hold the can upside down.

2. When transferring it into another container, make sure to agitate it well beforehand.

3. While in use, agitate it at reasonable intervals.

※Our magnetic stirrer is available for agitating the solution while in use. (product code: MGP-101)

3. Applying and drying DRYSURF

How to apply it

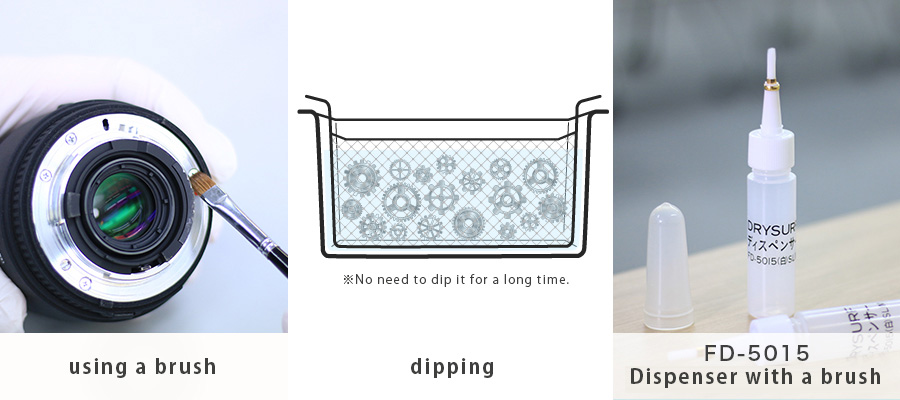

Apply DRYSURF after agitating well by

1. using a brush

2. dipping

3. using dispenser (with a brush FD-5015 / machine) etc. One application (dipping) forms an effective layer.

*No need to dip it for a long time.

How to dry

1. Natural drying 2. Blowing

After applying DRYSURF, dry it well until the solvent evaporates. It will take a few seconds to a few minutes.

※Please note that drying time varies according to the product to which it is applied, shape of the parts and operation environment.

4. Suppressing the evaporation of DRYSURF solvent

It is necessary to suppress the evaporation of the solvent to maintain its concentration.

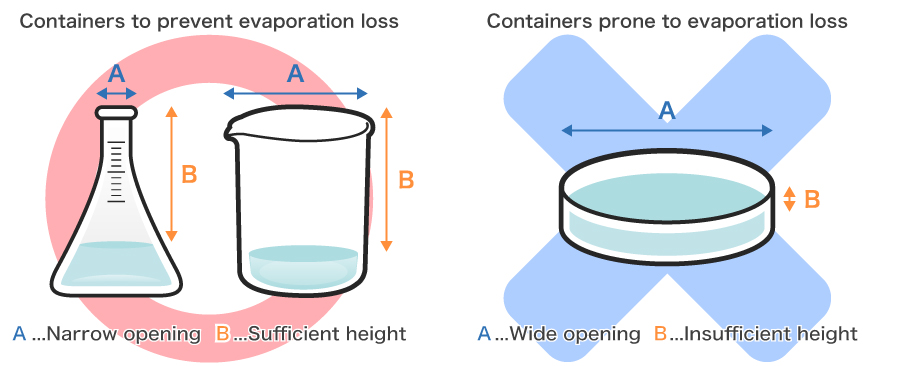

1. Processing tank should have minimum opening to avoid contact with outer air as much as possible (see below). E.g.) When applying with a brush, using a flask will reduce evaporation.

2. It is ideal to use a processing tank whose height from the surface of DRYSURF to the opening (B) is three times or more than the diameter of the opening (A) (see below).

※The steam is 8-10 times heavier than the air, acting like a lid on the liquid surface to prevent further evaporation.

3. Atmospheric circulation will accelerate evaporation. Using shield around the processing tank is effective.

4. Please be careful that strong agitation in an open tank will accelerate evaporation.

Storage of DRYSURF

1. Tightly stopper the container and keep it in dark, cold place.

・When storing, stopper the container tightly and store in cool and well-ventilated area avoiding direct sunlight.

・No need for cold storage.

2. Avoid long-term storage

・The longer the storage period, the more likely content gets separated and settled in the liquid.

3.Avoid foreign substance contaminationる

・Foreign substance such as dust or metal powder inside could cause damage on the surface when applied with DRYSURF.

・If water gets inside, it may result in corrosion of the inner surface of the can.

・Do not mix with other products or agents.

Safe handling of DRYSURF

1. Use in well-ventilated area

2. Thoroughly wash hands after use

Warranty period for DRYSURF

Warranty period is two or three years after manufacturing depending on the product (when unopened).

※Please contact us to find out the warranty period for your product. You can also find the information on the product label.